Infinite Switch Detailed Operation

On electric ranges, the common infinite switch (or simmerstat) uses Pulse Width Modulation (PWM) to control the amount of power delivered to the cooktop burner ¹.

Despite common misconceptions, PWM is not just reserved for DC voltage. It is simply a voltage (AC or DC) (also known as the carrier wave) that is modulated (manipulated, i.e. turned on and off) at a frequency and duty cycle that is determined by the modulating signal.

*To DONATE to the Tech Circuit – CLICK HERE*

*CLICK HERE FOR THE FREE ELECTRICITY MICRO-COURSE FOR APPLIANCE TECHNICIANS*

For an infinite switch, the modulating signal is the on/off action of the internal bimetal strip (as determined by the knob position and the cam’s pressure against the strip) and the carrier wave is the 240VAC sine wave at 60Hz. This strip is heated either by its own resistance or a separate proximate resistor that passes current to the cooktop burner – causing it to break the circuit by opening a switch. Thus the modulating mechanism is the asymmetrical thermal expansion and contraction of the bimetal strip, with the underlying agent being the current through the circuit.

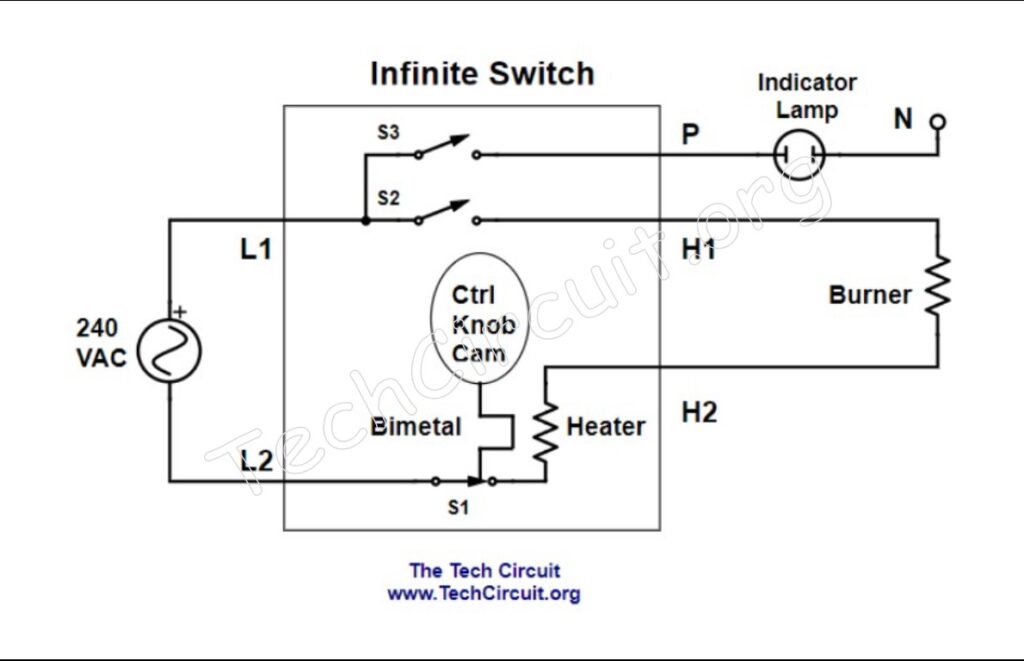

The figure below depicts a common infinite switch’s internal circuit.

Operational walk-through

When the knob is turned on, S2 and S3 close – so that L1 appears at the P and H1 terminals on the right of the infinite switch as in Figure 1. This turns on the indicator lamp and provides the potential for one side of the burner. L2 is passed through S1, but whether S1 is closed or not depends on the knob’s setting. The bimetal strip consists of 2 different metals that expand and contract at different rates when heated by the resistance of either the strip or an external resistor. When fully cooled, the strip closes S1, when heated, S1 is opened. The more force that exerted against the strip by the knob cam, the less S1 is dependent on the strip’s reaction to temperature. This is how S1 is in effect, pulse width modulated. For more detailed information on how an infinite switch uses PWM, click here.

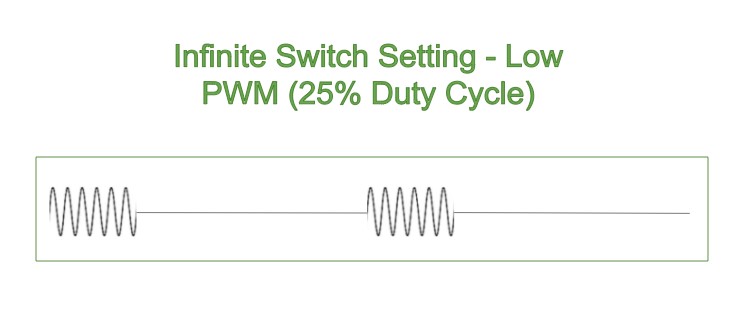

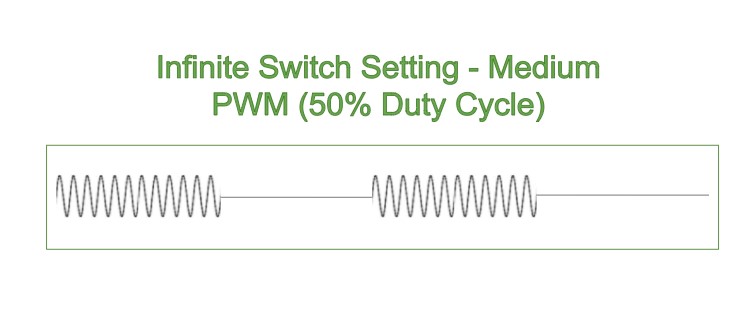

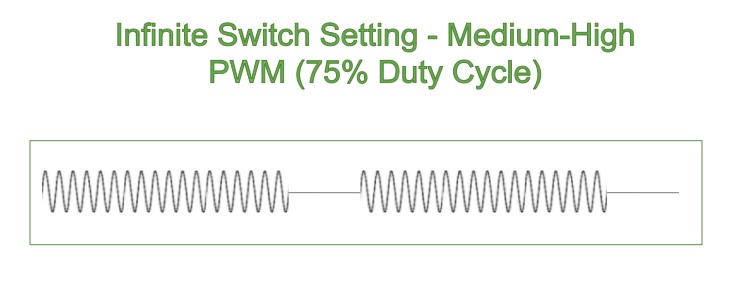

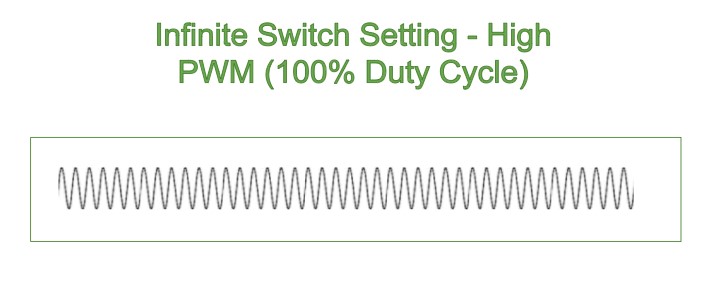

The PWM duty cycle determines how much power is delivered to the load by varying the percentage of time that the voltage is turned on within each time period. The time period and thus frequency of the modulation in an infinite switch is variable (unlike traditional PWM applications – such as motor control and LED lighting), and determined by knob controlled cam that presses against the bi-metal strip. The more force, the higher the frequency and duty cycle. The less force, the lower the frequency and duty cycle. The following oscilloscope-like images show the waveforms for different heat settings.

The figure below shows the pulse-width modulated waveform for an infinite switch set on low and minimal force exerted by the cam.

The figure below shows the pulse-width modulated waveform for an infinite switch set on medium and moderate force exerted by the cam.

The figure below shows the pulse-width modulated waveform for an infinite switch set on medium-high and moderately high force exerted by the cam.

Finally, the figure below shows the pulse-width modulated waveform for an infinite switch set on high or 100% duty cycle with S1 forced closed by the cam.

In the preceding figures, the duty cycle determines the percentage of power delivered to the load. Since the voltage and current are both at 100% for the time the switch is closed, the delivered power is directly proportional to the duty cycle. Thus a 50% duty cycle delivers 50% power and thus 50% heat.

The reason for using PWM on a stovetop burner is the same as for LED lighting and motor control. There is almost no waste power when turning a switch on and off, as opposed to other methods of power reduction. That is because a switch has (ideally) has no resistance or voltage drop (and thus no power dissipation). Using a resistor to drop the voltage would certainly reduce power at the load – but would dissipate a lot of wasted heat. In the case of a cooktop burner, the power reduction resistor would have to be huge and would dissipate almost as much heat as the burner itself.

How Can an Infinite Switch Implement PWM?

Those familiar with PWM might think it is odd for the PWM frequency is slower than that of the voltage that it modulates. And yes, it is typical that PWM switching frequencies are higher than the carrier frequency (often DC), since PWM by definition, breaks a signal into smaller parts.

However, 240V RMS AC voltage is the effective equivalent of DC voltage for resistive loads in terms of power delivery – and of course the frequency of DC is zero. So the infinite switch doesn’t care about the carrier frequency and is simply breaking up the delivered power into a percentage of what would be delivered if it were just a closed switch. So if you hardwired 240VDC to a 24 ohm cooktop burner, you’ll have 10 amps and 2400 watts. If you instead modulate that via PWM at 50%, you’ll deliver 1200 watts. If you do the same two things above with 240VAC RMS, you’ll get the same result. If you instead use an infinite switch that is switching at 10 Hz (0.1 second period), but is on 50% of the time (0.05 sec on, 0.05 sec off), you’ll deliver 1200 watts – which is why the function of an infinite switch for resistive loads is the equivalent of PWM.

You’ll even find a Wikipedia entry that compares the infinite switch’s operation to that of PWM here.

Don’t forget:

“Diverting 10 min/day of social media time towards learning something new, is 5 hours of newfound monthly knowledge.” – SM

To DONATE to the Tech Circuit – CLICK HERE

Alphabetical Links to all Tech Circuit Articles and Blogs – CLICK HERE

Links to all Tech Circuit Cheat Sheets/Field References for Appliance/HVAC Techs – CLICK HERE

For additional electrical and electronics learning material for field techs, visit our homepage at http://www.TechCircuit.org or our Facebook group at https://www.facebook.com/groups/746823709133603.

References

————————————————————————————————————

1. Pulse-width Modulation, Wikipedia, Power Delivery, Paragraph 7 – Simmerstat, https://en.wikipedia.org/wiki/Pulse-width_modulation

————————————————————————————————————

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.