How Resistance Damages High-Current Connections

Blocks, Connectors, and Cords

We’ve all seen it. Burned up terminal blocks. Heat stressed quick-connects. Blackened and melted dryer or range cord plug prongs. What causes this though? Yeah, we all know its because of a loose connection. But why does it happen? It’s really Ohm’s law and the power equation causing several things to occur in a very predictable way:

- Loose connection presents resistance to the circuit: The resistance of a good, solid, high-current connection should be well under 50 milliohms. That’s less than 1/20th of an ohm. Low resistance connections can last the life of the appliance while carrying their expected current.

- Relatively high-resistance creates a voltage-divider: Where most loads in an appliance or HVAC unit are part of a single-load circuit, a loose connection causes an unintended “voltage divider” to occur. This transforms a single-load circuit into a dual-load circuit by causing a voltage drop across the resistance that results from the loose connection. Every load performs work (power output). In this case the work is manifested as heat being output at the loose connection. It also causes power to be lost at the primary load as it is effectively spread among what is now two loads.

- High heat degrades the connection and further increases resistance: As the loose connection heats up the connection point expands at different rates – further loosening the connection. As well, the metal conductors at that point experience a change in their properties, which increases their resistance. The result is a “runaway” effect where resistance increases, heat increases, resistance further increases, etc.

Quick Connect Resistance Scenarios

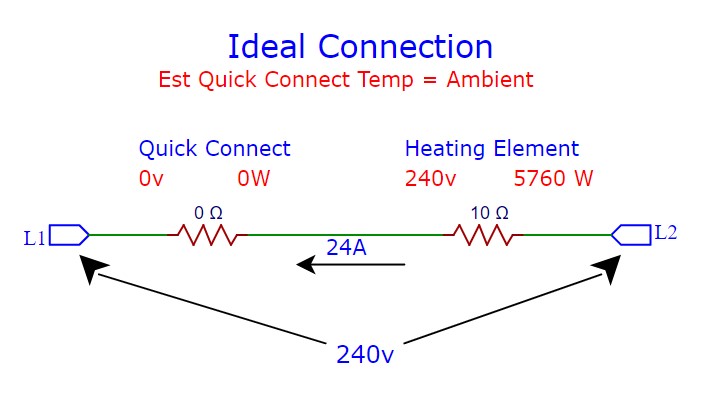

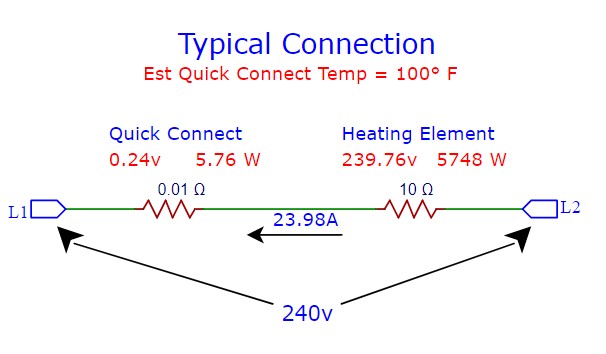

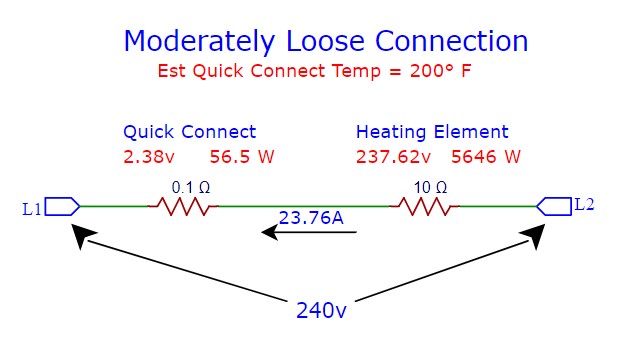

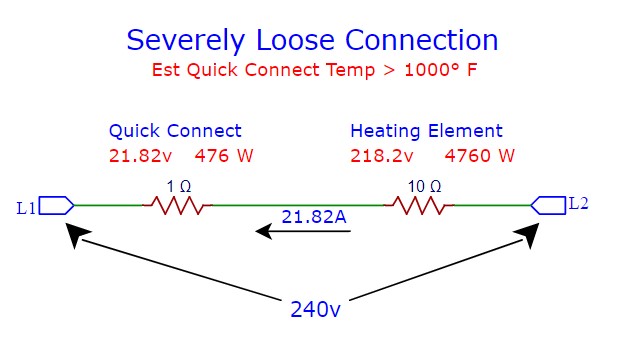

Below are four quick connect terminator scenarios, along with their resistance, voltage drop, heat output in wattage, and estimated temperature. They are as follows:

- Ideal Connection – Resistance = 0 Ω, Temp = Ambient Temp

- Normal Connection – Resistance = 0.01 Ω, Temp =100° F

- Moderately Loose Connection – Resistance = 0.1 Ω, Temp = 200° F

- Severely Loose Connection – Resistance = 1 Ω, Temp > 1000° F

Stop the Division

The voltage divider and resulting high-heat connection can largely be avoided. Prevention is really the key. Technicians can easily mitigate the risk of them occurring by following simple steps.

- Inspect all high current connections when working on appliances and other equipment

- When disconnecting or installing any high current device, make sure they are tight.

- Terminal blocks should be tight, but not too tight. Overtightening them can strip the threads – causing poor connections.

- Quick connects are usually loose once they have been disconnected and reconnected. This can be mitigated by squeezing them with needle-nosed pliers prior to reconnection or replacing them if they don’t respond well to tightening.

Alphabetical Links to all Tech Circuit Articles and Blogs – CLICK HERE

Alphabetical Links to all Tech Circuit Cheat Sheets/Field References for Appliance/HVAC Techs – CLICK HERE

To donate to the Tech Circuit – CLICK HERE

For additional electrical and electronics learning material for field techs, visit our homepage at http://www.TechCircuit.org or our Facebook group at https://www.facebook.com/groups/746823709133603 or our YouTube Channel

at https://www.YouTube.com/c/TheTechCircuit

TC

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.