What does the term “Thermal Inertia” have to do with oven pre-heating? Quite a bit actually. You might have noticed that in many electric ranges, both the bake and broil elements work to preheat the oven, but not simultaneously.

The Preheating Process

For many electric ranges the preheating process involves both the bake and broil elements working in concert to accelerate pre-heating, and to more evenly cook the food. Both elements in this case though are generally not on simultaneously. Rather, the broil and bake elements “toggle” back and forth to achieve their collective goal. The ranges and ovens that employ this method exploit “thermal inertia” in their design.

What is Thermal Inertia

What is inertia? Simply put, it is the resistance to change. In the mechanical world, bodies in motion, tend to remain in motion. Bodies at rest tend to stay at rest. This concept also applies to stored heat, because after all, heat energy is motion at the molecular level.

Thermal inertia, in this blog’s context, simply relates to an object’s (heating element’s) tendency to remain warm after it is de-energized. In other words, based on the element’s “heat capacity”, it takes a certain amount of time for it to cool down. This fact is exploited to help more quickly pre-heat ovens.

More accurately, we’re talking about differential thermal inertia. It only means that it takes much less time to heat each element, than for them to cool down. This is because a lot of power is expended for the former.

Thus, when the bake element is the main source of heat for an electric oven, it generally doesn’t have the sole capacity to pre-heat the oven in a reasonable amount of time nor often evenly maintain certain set higher temperatures (in excess of 300 degrees Fahrenheit). So what most ranges do during pre-heat, is to “toggle” back and forth between the bake and broil elements, with the duty cycle of the bake element being about 80% and the broil element being around 20%. The reason for “toggling” is explained shortly, but for now, just know that when the bake element is de-energized, and the broil element energized, both elements are effectively heating the oven cavity (because of their respective thermal inertia).

So the bake element will come on for a period of time, glow orange, and then turn off. The moment the bake element turns off, the broil element is energized. Although the broil element usually won’t glow orange during pre-heat, it is emitting plenty of heat. Then, the broil element will de-energize, and the bake element will energize. At this point, both elements are putting off heat, even though only one of them is on for any moment in time.

So Why the Toggling?

Why even toggle the elements rather than energize both simultaneously (although some electric ovens actually do that)? Primarily, it saves energy and requires a lower capacity electrical circuit. Particularly for an electric range, which can potentially draw a lot of current because of the cooktop, this is a significant fact. Thus the toggling helps keep the maximum current draw of the range under 50 amps because the average 14 amp current draw of the broil element is not added on top of all other loads. Rather it is toggled with the bake element load. There are other benefits too. The incremental cost of installing greater than 50 amp service to the range, may be quite high. As well, the heat loss in house wiring is exponentially a function of current draw. Any electrical current savings results in a corresponding square of waste heat savings from the wiring.

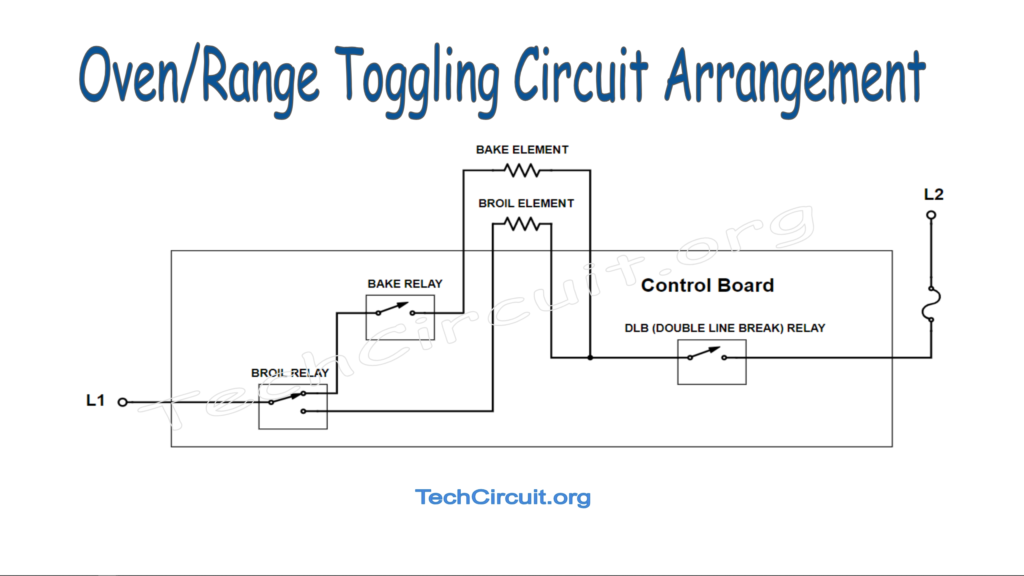

Above is a schematic diagram of a bake/broil element toggling relay arrangement that is responsible for circuit “switching” in the described process. The specific arrangement not only facilitates “toggling”, but helps prevent both elements from coming on at the same time in the event of a fused relay. This mitigation is accomplished using a SPDT relay for the broil function.

Even Pre-heating and Cooking

It may go without saying that having a heat source only at the bottom of the cavity (even though heat rises), may cause food to heat unevenly. Providing an additional heat source from the top thus promotes more even heating both from a convective, as well as radiant heat standpoint. This heat energy is facilitated by the broil element both when it is energized, and from its thermal inertia when de-energized. This primarily occurs during preheat, but to some extent may be utilized during the full bake cycle.

Test your Knowledge!

Test your knowledge with this comprehension quiz. Your score will be automatically reported at the end, and answers to incorrectly responded questions will be shown:

Thermal Inertia Quiz

Summary

A large majority of electric ranges and even built-in ovens use thermal inertia to accelerate the preheating process. In this way, both the bake and broil elements heat the oven cavity, while only one of them at a time is energized. This is accomplished by an arrangement of relays that, in conjunction with the board’s firmware algorithm, “toggle” the elements on, back and forth. Once the broil or bake element is de-energized, much of the element’s heat remains in the form of stored heat, which along with the energized element, serves to more quickly and evenly preheat the oven cavity. Although some ovens energize both elements at the same time, this will normally be found in built-in ovens with no cooktop.

Some of the advantages of “toggling” elements during preheat are:

- Accelerated pre-heat vs. bake-element only.

- Less current draw and no need for an incrementally high current capacity circuit that is more expensive to install.

- The lower current draw that results in exponentially less waste heat in the house wiring.

- More evenly preheated and cooked food.

For more information about electric range function, element resistances and current draws, common symptoms and causes, please see our Electric Range Cheat Sheet at:

https://techcircuit.org/electric-range-electronics-cheat-sheet/

Don’t forget:

“Diverting 10 min/day of social media time towards learning something new, is 5 hours of newfound monthly knowledge.” – SM

To DONATE to the Tech Circuit – CLICK HERE

Alphabetical Links to all Tech Circuit Articles and Blogs – CLICK HERE

Links to all Tech Circuit Cheat Sheets/Field References for Appliance/HVAC Techs – CLICK HERE

For additional electrical and electronics learning material for field techs, visit our homepage at http://www.TechCircuit.org or our Facebook group at https://www.facebook.com/groups/746823709133603.