Intro

Here are some images of Whirlpool Dryer Motor Relay contacts in different stages of use and failure. These are all images of the original Omron relays found on the dryer control boards.

The first image shows new/unused Omron relay contacts. Notice the shiny protective finish as well as the concavity and convexity of the lower and upper contacts respectively – which improves alignment and increases the contacted surface area. These relay contacts should have a resistance of less than 100 milliohms.

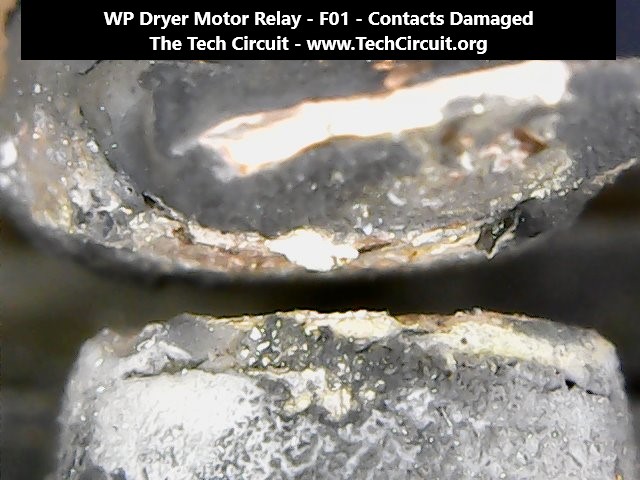

The next image shows contacts from an Omron motor relay in a dryer that had an F01 error and a blown-out solder connection on the back of the board. These relay contacts had a resistance of 800 milliohms or 0.8 ohms – which is very high when you are passing a lot of current through them. This will result in heat build up and accelerated degradation.

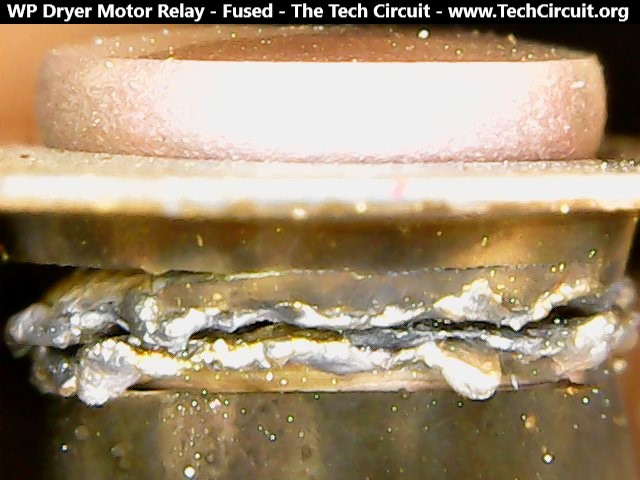

The next image shows an Omron relay with fused contacts where the motor would run whenever the door was shut and the power was on, but the cycle was not selected. These contacts were so degraded, that they welded themselves together.

You can easily check the resistance of relay contacts indirectly using Ohm’s Law. It’s easy. Just measure the current going through them by checking the amp draw of the associated element or load with a clamp meter, then check the voltage across the contacts. Take the voltage and divide it by the current. If you get greater than 300 – 400 milliohms, your relay contacts are degraded.

Look at it this way. If you have a bake element drawing 10 amps through 300 milliohm relay contact, those contacts are generating (10 x 10 x 0.3) or 30 watts of power. If you take, for example, all the heat from a 30 watt incandescent bulb and concentrate it in a small space like that of relay contacts – you have a lot of heat at the contacts – which will quickly accelerate their demise. At minimum, the mid to long term outlook for that relay (or its solder connections on the board) is not good.

Don’t forget:

“Diverting 10 min/day of social media time towards learning something new, is 5 hours of newfound monthly knowledge.” – SM

To DONATE to the Tech Circuit – CLICK HERE

Alphabetical Links to all Tech Circuit Articles and Blogs – CLICK HERE

Links to all Tech Circuit Cheat Sheets/Field References for Appliance/HVAC Techs – CLICK HERE

For additional electrical and electronics learning material for field techs, visit our homepage at http://www.TechCircuit.org or our Facebook group at https://www.facebook.com/groups/746823709133603.

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.