Introduction

If you get the the expected “S” during a Whirlpool Refrigerator Jazz Board model’s defrost system diagnostic mode, and it changes to the dreaded “O” after only a minute or two, you likely have “ohmic self-heating” of the bimetal thermostat.

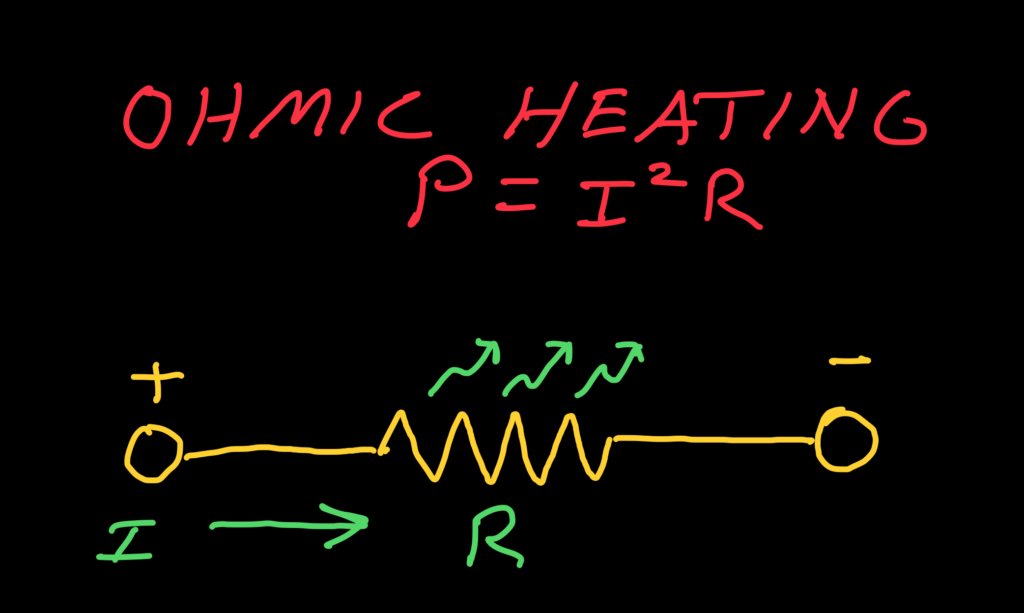

What is Ohmic Self-Heating?

Ohmic self-heating is based on the concept of “ohmic heating”, which is a direct conversion of electrical energy into heat as per Joule’s law. This states that power (heat output), is equal to the current squared times resistance, or more familiar to us, I²R. This phenomenon is the basis of all electrical resistive heating, such as that utilized by dryers (heating element), and electric ovens (bake element). It has proven to be quite useful and convenient for the masses, and for two centuries, an ubiquitous form of simple energy conversion.

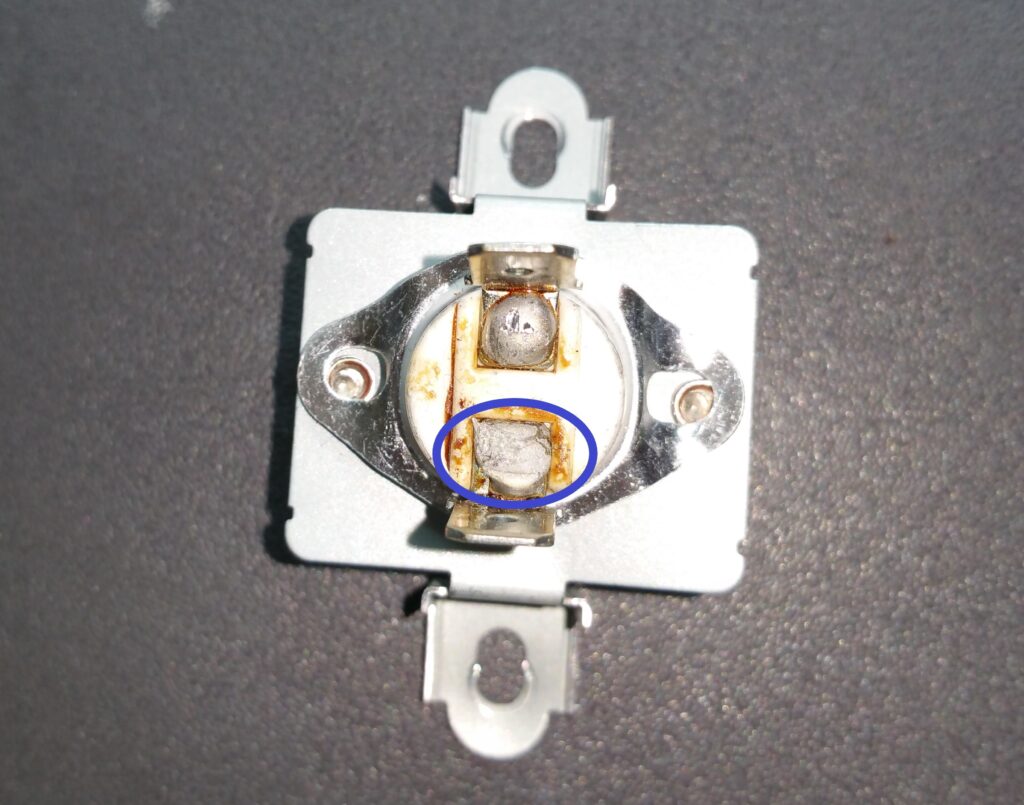

However, ohmic self-heating of thermostats is not so useful. It occurs when the connection points or contacts wear out over time and develop a higher than normal resistance. This resistance, along with the current that passes through that thermostat, causes heat to dissipate from the contacts themselves. This heat is either directly conducted to the fusible link (or bimetal strip), or builds up in the body of the thermostat.

How are Thermostats Affected by Ohmic Heating?

Ohmic self-heating of thermostats or cutoffs leads to a premature “cut-out”, which occurs well below it’s target cut-out temperature. This will generally open the circuit in which the thermostat resides, causing unintended, and often undesirable behavior of the circuit.

What are the Typical Symptoms of Ohmic Self-heating?

Defrost Bi-Metals

For ohmic self-heating of defrost bimetals, the usual complaint is that the refrigerator section is not cooling well and that the freezer inner back-wall (evaporator cover) is covered with frost. This is due to the defrost heater not sufficiently melting the frozen condensate on the coils. The defrost bimetal’s job is to “cut-out” when it reaches a certain temperature, which terminates the defrost cycle. However if ohmic self-heating occurs, the bimetal will prematurely “open up” and result in an incomplete defrost cycle.

Other types of thermal devices subjected to this phenomena are microwave TCOs (thermal cutoffs), dishwasher thermal fuses, and dryer thermal cutoffs.

Microwave TCOs

Microwave TCO’s are often “tripped” by the heat dissipated at one of the quick connectors attached to it. Once a small amount of resistance occurs at one of those connections, heat dissipates, resistance increases, and a snowball effect ensues, which can ultimately trip the TCO.

Dishwasher Thermal Fuses

Dishwasher thermal fuses are often subject to this occurrence as well. this prompted a specific installation procedure, per a kit, that completely bypasses any need to make connections at the fuse itself – effectively maintaining a sufficient “thermal distance” between the fuse and connections.

Dryer Thermal Cutoffs

A common occurrence with dryer thermal cut offs is that when one is replaced the quick connects are pushed on it in a much looser fashion than when originally installed. The small amount of resulting resistance, along with the 20+ amps of current that flows through those contacts, can cause the thermal cutoff to self heat and prematurely trip. This is why it is very important to tighten those connectors and make sure that those types of high contact connections are solid.

Mitigation of Ohmic Self-Heating

There is nothing we can do about ohmic degraded defrost bimetals – other than to be aware of their existence and know how to identify them. We can though, head-off such an effect on thermal cutoffs and other devices that are subject to such degradation by loosely connected terminals. We can tighten quick connects so that they push on snugly – greatly reducing their inter-resistance.. We can install thermal fuses as instructed, when they come with a kit that bypasses any connections at the fuse itself. Being acutely aware of how ohmic heating can affect high-current connections and contact, is the first defense to related failures.

Conclusion

Ohmic self-heating of thermostats and other types of thermal devices can cause unintended consequences due to resistive heating of either internal contact or loose connections associated with those devices. Defrost bi-metals that are affected by this condition can easily fool technicians into thinking that they are OK when only a quick defrost system continuity test is conducted, rather than a when given enough time for ohmic self-heating to manifest into a premature cut-out. Other types of thermal devices, such as thermal cutoffs, are commonly self-heated by loose connections in close thermal proximity to them – prematurely cause them to trip.

Don’t forget:

“Diverting 10 min/day of social media time towards learning something new, is 5 hours of newfound monthly knowledge.” – SM

To DONATE to the Tech Circuit – CLICK HERE

Alphabetical Links to all Tech Circuit Articles and Blogs – CLICK HERE

Links to all Tech Circuit Cheat Sheets/Field References for Appliance/HVAC Techs – CLICK HERE

For additional electrical and electronics learning material for field techs, visit the following links:

Homepage at http://www.TechCircuit.org

Facebook group at: https://www.facebook.com/groups/746823709133603

Youtube Channel: https://www.youtube.com/@TheTechCircuit

We are a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.